Original title: How to select MES system? Main contents of MES production management

Manufacturing activities are the core activities of manufacturing enterprises. As the entity unit of manufacturing activities, planning objectives and the realization of enterprise value, workshop management is the focus of enterprise management. With the rapid development of manufacturing industry, MES is the focus and current hotspot of manufacturing enterprise information automation system, and the key to the transformation and upgrading of manufacturing industry and the development of advanced manufacturing industry. Therefore, MES has become the application and development hotspot in recent years.

This article will introduce you: 1. the main content of MES production management, 2. the factors affecting the selection of MES system; 3. MES products suitable for small and medium-sized manufacturing companies

1、 Main contents of MES production management:

First of all, we need to understand why we need to carry out production management. Subsequent work arrangements can be made according to the tasks and objectives of production management. In fact, it is very simple. It is consistent with the goal of general economic activities. The purpose of production management is to maximize the output with as little input as possible, that is, to achieve the best economic benefits.

Photo source: Jian Daoyun, official website: //s.fanruan.com/lwl9n

1. The tasks of production management include:

Achieve production objectives and plans : The primary objective of production management should be to make the operation meet the requirements of the established production plan, and achieve the target of expected production variety, quality, output, production period and production cost;

Systematic production management : According to the specific requirements of the enterprise's objectives and in combination with the enterprise's situation, set up a production system that is technically achievable and cost-effective, and form a production system that allows both material and environmental conditions;

Timely optimize production plan : Work in strict accordance with the production plan and formulate a plan for optimizing the operation of the production system;

Get through production management and other management systems: Combine the production system with other systems of the enterprise, so that the production management of the enterprise is closely combined, and timely and effectively adjust various relationships inside and outside the production process of the enterprise.

2. Objectives of production management:

Complete all tasks according to the production plan: Try to meet the requirements of product variety, quality, output, cost, trading period, environmental protection and safety, and ensure the effective operation of the production system;

Reduce production costs and improve enterprise competitiveness: Reduce material consumption as far as possible, control price production costs, shorten production cycle, reduce work in process, reduce occupied production funds, effectively use the enterprise's manufacturing resources, and constantly improve the enterprise's economic efficiency and competitiveness as the goal;

Diversified production system, adapt to market changes, and timely adjust products: In order to adapt to the rapid changes in the market and environment, efforts should be made to improve the flexibility of the production system, so that enterprises can constantly launch new products according to market demand, and the production system can adapt to diversified production, quickly adjust production, and change varieties.

3. The content of production management includes:

Organize production. In addition to the initial preparations such as selecting the plant site and arranging the plant, you also need someone to take action, so you should also organize the production line, implement the labor quota and labor organization, and set up the production management system;

planned production. The prerequisite for timely provision of "food and grass" is that "the troops are not moved, and the food and grass go first". The production plan, production technology preparation plan and production operation plan should be made as soon as possible;

Control production. That is to control production progress, production inventory, production quality and production cost.

According to the basic business of production management, we can simplify production management into the following four processes:

Each process is the overall service for production management, and is an indispensable part of production management.

2、 Influencing factors of MES system selection

① Price factor

Small and medium-sized enterprises have limited funds and their prices are highly valued. The investment in MES production management system generally includes Software cost, service support cost, secondary development cost, and income lost due to implementation delay Etc.

In terms of price, the performance, function, technical platform, quality, after-sales service and support of the software should be comprehensively considered, and investment benefit analysis should be done, including capital profit rate and investment payback period.

It is also necessary to consider the implementation cycle and difficulty, so as to avoid that the implementation time, secondary development or customization time is too long, which will affect the realization of benefits. On this basis, we should make a comprehensive balance and choose a solution with high cost performance.

② Personalized needs

SMEs of different industries and sizes have different needs for MES, so the products with strong industry segmentation and MES product targeting are the first choice for enterprises. For manufacturing enterprises, software should be considered first Whether it is suitable for the production type of your own enterprise , such as textile, clothing, chemical industry, hardware, clothing, food, medicine, electronics, machinery manufacturing and other industries. Professional products have strong characteristic research and targeted development in the industry, and their product module design, process design and management requirements have strong industry characteristics.

In addition, with the continuous accumulation of practical experience in the industry, we can also become familiar with relevant problems, apply the right medicine to the case, and use the rich practical experience before to solve them easily. These are the most direct manifestations of professionalism. In addition, for small and medium-sized enterprises with weak informatization, the first thing to be improved is the financial module, which uses informatization tools to standardize financial processes.

③ Secondary development performance

It is impossible for MES manufacturers to have the ability to develop MES products that meet the needs of users in all industries and all industry chain enterprises 。 Therefore, no MES product can fully meet the needs of enterprises, and there will be more or less customization and secondary development needs. Especially in the manufacturing industry, because the manufacturing links of manufacturing enterprises vary widely in different industries, are highly complex and personalized, to meet the needs of different users of the information management system in the production and manufacturing links, it needs an open product development environment or interface, provide necessary development tools, and ensure that the development tools are easy to learn and use.

④ Post implementation services

The later implementation and maintenance of MES for small and medium-sized enterprises is also important, because the informatization level of small and medium-sized enterprises is low, and the professional quality of personnel is uneven, and various problems may be encountered in the implementation process of MES, so it is necessary to rely on the good follow-up services of MES service providers to help small and medium-sized enterprises solve them together.

Select companies that have perfect after-sales service mechanisms to provide different types of services in a timely manner at multiple locations in the future. After sales service is required to be provided in various forms, such as remote login online assistance, 24-hour telephone support, and on-site service of local branches. It should be noted that the services provided by professional MES manufacturers must be standardized and will not change due to the differences in regions and service personnel, which requires MES manufacturers to have a set of standardized service system.

3、 MES products suitable for small and medium-sized manufacturing companies

1. Reference factors:

From the perspective of cost performance: MES products for small and medium-sized enterprises have low cost and can standardize the process according to the characteristics of small and medium-sized enterprises;

From the perspective of adapting to local manufacturing enterprises: Foreign software manufacturers have no advantages over domestic MES manufacturers. Domestic MES manufacturers are more familiar with and easy to implement and adjust software based on their own characteristics, which can better meet the needs of enterprises and reduce risks;

From industry experience: Comprehensive management software providers have an advantage over professional MES software providers in terms of industry fit ability. Although comprehensive management software has advantages in stability and other aspects, it needs to pay a high price to meet personalized needs.

2. Jiandaoyun production management system

Official website: //s.fanruan.com/lwl9n

As a domestic product, Jane Daoyun has a good understanding of the characteristics of the domestic manufacturing industry. Its MES production management system is designed for small and medium-sized manufacturing enterprises. The system integrates the production work reporting system, equipment management system and warehouse management system, and integrates production, equipment patrol inspection and inventory management to operate systematically.

Main highlights of the production management system:

1) One code to one order

When making a production plan, you can fill in a plan online. One plan corresponds to a two-dimensional code. Scanning the code can view the production progress at any time and report production work.

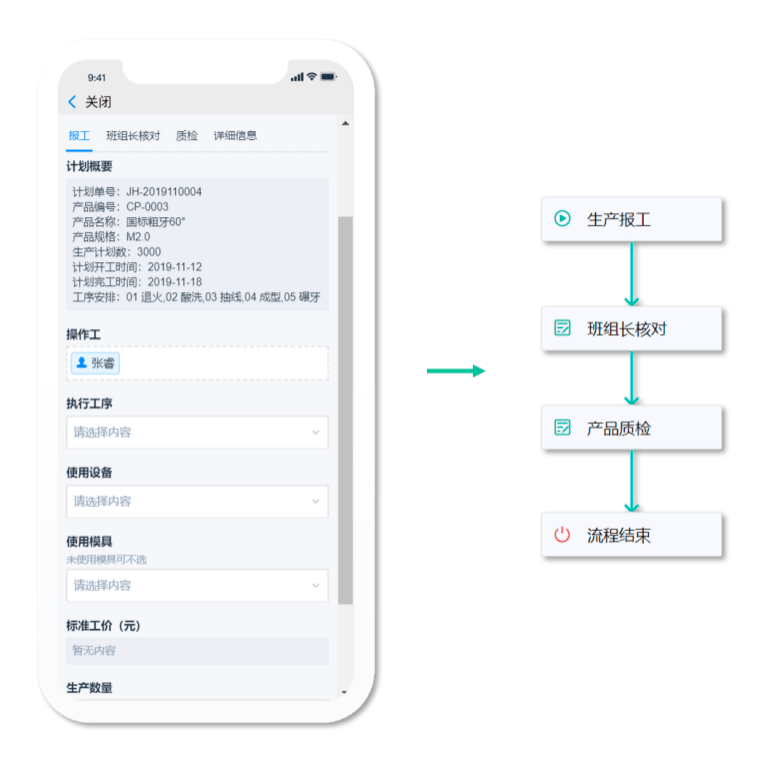

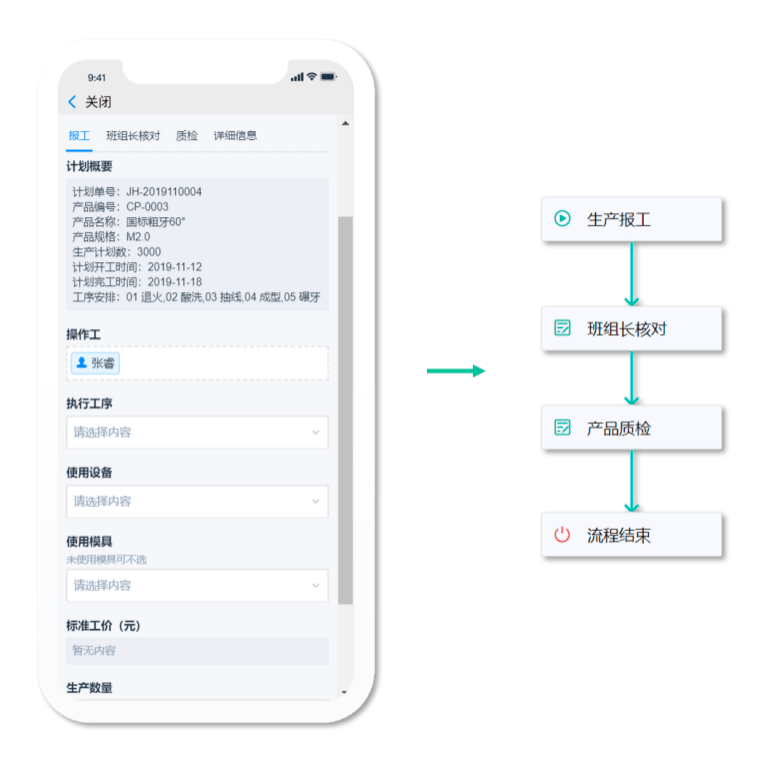

2) Paperless work reporting

After making the production plan, employees can directly scan the flow card for work reporting and enter their own output for the shift; Through the check of the team leader, it can avoid over reporting, false reporting and missing reporting; After the completion of work reporting, it will be directly transferred to quality inspection for quality inspection, fill in the number of good and waste products, and paperless work reporting throughout the process.

3) Real time monitoring of output

After completing the plan formulation and production report, the system can monitor the output. The dashboard can intuitively display production data, and is also equipped with exception alerts, which can be viewed by enterprise managers on their mobile phones at any time.

4) Production Tracking Query

In the production process, the planned production, quality inspection, completion and responsible person can be tracked in real time, and the enterprise management can view the plan progress at any time; In addition, once the product quality is abnormal, enter the document number to query the complete file.

5) Data visualization analysis

After the production is completed, the data can also be visualized and analyzed through the dashboard. The system can analyze and display multi-dimensional data according to the submitted data, such as team ranking, defect rate analysis, process optimization, production efficiency, etc.

The overall framework of the manufacturing enterprise information automation system is based on the three-tier structure model of "plan execution control" proposed by MES, with ERP as the main body to form the upper layer of various enterprise level resource planning and decision analysis applications, with MES as the main body, and combined with CAD/CAM to form the middle layer applications around product design and manufacturing process management, including production line The monitoring and control of devices and equipment at different levels are established as the automation application of the lower level, and the information integration and function integration between layers are realized through advanced software architecture technology. The development of this framework presents the status quo of "two heads first, middle backward".

It is inevitable that MES will become the key to transformation. Therefore, it is an important step for manufacturing enterprises to choose an appropriate MES production management system. I hope this article will help you. Go back to Sohu to see more

Editor in charge: